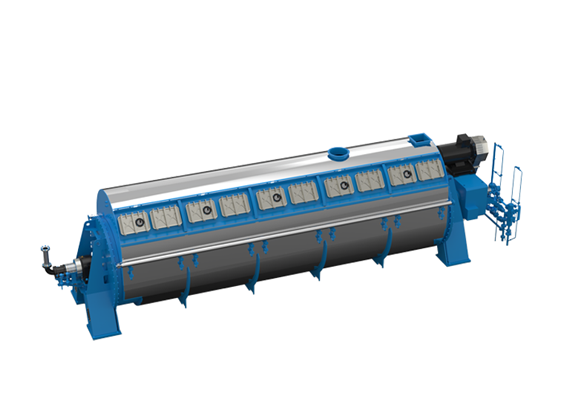

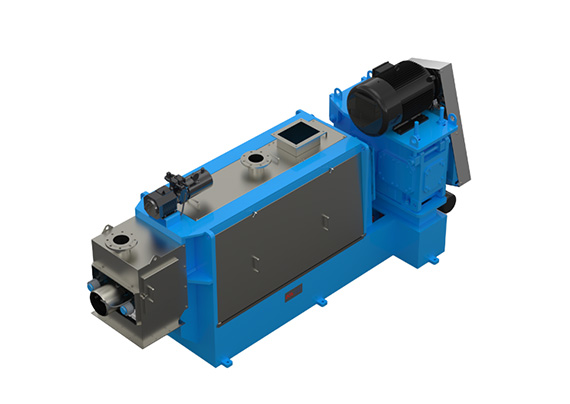

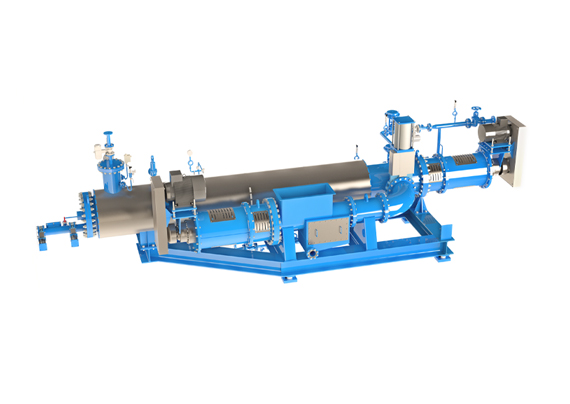

Disc Dryer

Description

Disc Dryer Application

Jiangsu sunrise disc dryer is indirect steam heated and designed for continuous cooking or drying of animal by-products or fish.

A disc dryer is a type of industrial equipment used to dry various materials, such as sludge, sewage, and food products. The material to be dried is spread out evenly over a rotating disc, where it is heated and agitated by a series of scrapers, paddles, or other mechanical devices. The heat and agitation causes the moisture in the material to evaporate, leaving behind a dry, solid product. Disc dryers are commonly used in the food, chemical, and waste management industries.

Design characteristics

1. The wet material is fed into the dryer through the inlet at the dryer end. After water evaporates, the material is sent to the other end through the variable speed screw conveyor.

2. The rotor consists of a central pipe on which vertically arranged and parallel discs with double walls have been welded.

3. This design results in a concentrated heating surface offering maximum evaporation capacity in a compact design.

4. Disc dryer is designed running under 6-10 bar steam pressure. Only one pressurized stuffing box must be maintained.

5. The stator of disc dryer is manufactured in stainless steel. The rotor can be designed with mild steel or stainless steel, depending on the characteristics of dry product.

6. The product is different, the feeding speed is different, can be used different spade and agitator to adjust the feeding speed.

7. Disc dryer complies with GB national standards and each machine is produced, inspected and tested in accordance with GB pressure vessel standard and regulations.

Technical parameter

| Disc dryer model | Specification | Heating area | Power | Shipping Parameter | |||

| Length | Width | Height | Weight | ||||

| m2 | kW | mm | mm | mm | T | ||

| SWGZ1228 | 1228 | 60 | 45 | 7750 | 2050 | 2600 | 22 |

| SWGZ1242 | 1242 | 90 | 45 | 9700 | 2050 | 2600 | 26 |

| SWGZ1537 | 1537 | 110 | 45 | 9050 | 2200 | 3200 | 31 |

| SWGZ1542 | 1542 | 130 | 45 | 9750 | 2200 | 3500 | 37 |

| SWGZ1850 | 1850 | 215 | 75 | 11100 | 2560 | 3500 | 52 |

| SWGZ2050 | 2050 | 250 | 75 | 11300 | 2800 | 3650 | 59 |

| SWGZ2550 | 2550 | 400 | 110 | 12200 | 3300 | 4150 | 84 |

| SWGZ2555 | 2555 | 441 | 110 | 12700 | 3280 | 4120 | 90 |

Depending on the thickness of disc.The size and weight maybe different depending on the application and material specification.

Disc Dryer FQA

Q: What is a Disc Dryer?

A: A Disc Dryer is a type of industrial drying equipment that uses a rotating disc to dry materials through a combination of heat, air flow, and agitation.

Q: What materials can be dried using a Disc Dryer?

A: Disc Dryers can be used to dry a wide variety of materials including powders, granules, pastes, and slurries. They are commonly used in the food, chemical, and pharmaceutical industries.

Q: How does a Disc Dryer work?

A: A Disc Dryer typically consists of a rotating disc that is heated by a steam or thermal fluid jacket. The material to be dried is fed onto the disc, where it is agitated and spread out by the rotation of the disc. Hot air is blown through the material, removing moisture and drying it.

Q: What are the advantages of using a Disc Dryer?

A: Disc Dryers are known for their high thermal efficiency, fast drying time, and ability to handle a wide range of materials. They are also relatively simple in design and easy to maintain.

Q: How to choose the right disc dryer for my process?

A: The choice of the disc dryer depends on the characteristics of the material to be dried, such as particle size, moisture content, and flowability. The production capacity, thermal and mechanical requirements and the available space for the dryer should also be considered.